Industrial Desiccant Rotor Dehumidification

Industrial rotary desiccant dehumidifiers with Swedish rotor technology. Engineered for low temperature operation, ultra-low humidity control, and continuous industrial duty in the most demanding environments.

Where Compressor Systems Fail, Desiccant Rotors Excel

Our industrial desiccant rotor systems use Swedish wheel technology — designed specifically for applications requiring low temperature operation (–20°C to +60°C), ultra-low humidity levels, and continuous industrial duty.

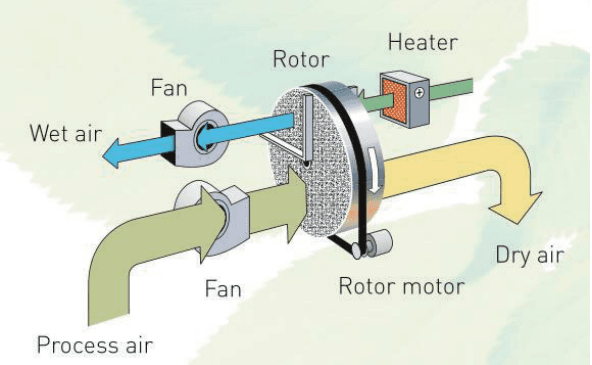

Unlike refrigerant-based dehumidifiers that freeze below 5°C and cannot achieve very low RH, desiccant rotor systems use adsorption and heated regeneration to deliver stable performance in pharmaceutical manufacturing, lithium battery dry rooms, electronics fabrication, and military installations.

With military-grade SCR temperature control, PTC ceramic heaters at 92% efficiency, and premium ABB/OMRON/Schneider components, these systems are built for precision, reliability, and integration into critical industrial processes.

Industrial Engineering Features

Certified ISO9000, CE, CCC — Built for pharmaceutical, military, and critical manufacturing

Swedish Desiccant Rotor Technology

Industrial-grade desiccant wheel from Sweden ensures continuous duty operation with exceptional reliability and longevity.

Extreme Temperature Operation

Operates reliably from –20°C to +60°C where compressor-based systems fail due to frosting.

Ultra-Low Humidity Capability

Achieves very low RH levels for critical applications requiring precise moisture control below 20% RH.

Military-Grade Temperature Control

SCR controller with PT100 high-precision sensor ensures accurate regeneration temperature up to 120°C.

PTC Ceramic Heater

92% heating efficiency with advanced PTC ceramic regeneration heater designed for industrial duty.

Premium Electrical Components

ABB, OMRON, and Schneider components ensure industrial panel integration and long-term reliability.

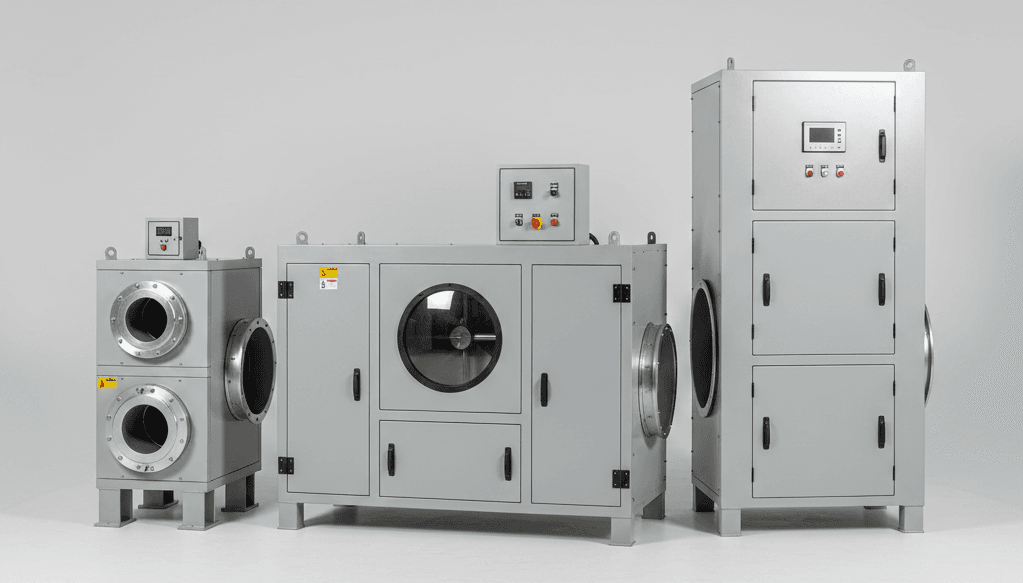

GZ Series Model Range

From compact laboratory units to large-scale industrial systems

Small & Medium Capacity

0.6 to 6.2 kg/h

GZB-200L to GZB-800L

Compact desiccant rotor units for laboratories, pharmaceutical rooms, and smaller industrial applications.

- ✓220V or 380V operation

- ✓45 m³ to 200 m³ space coverage

- ✓1.5 kW to 9.8 kW power range

- ✓7-15 days lead time

Large Industrial Systems

10.2 to 30.2 kg/h

GZB-1000L to GZB-4500L

Heavy-duty rotary desiccant systems for large manufacturing plants, warehouses, and critical facilities.

- ✓380V 3-phase power

- ✓80 m² to 350 m² area coverage

- ✓14.2 kW to 46.7 kW capacity

- ✓15-25 days lead time

Critical Industrial Applications

Proven in pharmaceutical, biotechnology, lithium battery, and defense sectors

Pharmaceutical Production

Tablet rooms, packaging areas, and sterile manufacturing require precise low-humidity control.

Lithium Battery Manufacturing

Dry rooms for battery cell production demand extremely low dew point environments.

Electronics & Semiconductors

Prevent corrosion and electrostatic discharge in precision electronics manufacturing.

Food Packaging & Storage

Extend shelf life and maintain quality in cold storage and processing facilities.

Museums & Archives

Preserve artifacts, documents, and artwork with stable humidity control in any climate.

Chemical Industry

Maintain process conditions and protect hygroscopic materials from moisture exposure.

Hospitals & Medical Facilities

Critical care areas, operating rooms, and medical storage require continuous humidity control.

Military & Civil Defense

Underground facilities, shelters, and military installations in challenging environments.

Laboratories & Research

University labs and research facilities need precise environmental control for sensitive work.

Why Desiccant Rotor vs. Compressor Systems

Low Temperature Failure

Desiccant rotor technology operates reliably at –20°C where compressor-based systems freeze and fail.

Ultra-Low Humidity Requirements

Achieves very low RH levels (<20%) essential for lithium battery, pharmaceutical, and semiconductor manufacturing.

Continuous Industrial Duty

No compressor cycling means stable, uninterrupted operation for 24/7 industrial processes and clean rooms.

Precise Process Control

Military-grade SCR controller and PT100 sensor provide exact humidity control for critical applications.

Technical Specifications

Swedish Desiccant Rotor Technology — Industrial Grade Systems

Need Industrial Dehumidification?

Our engineers will specify the optimal desiccant rotor system for your pharmaceutical, lithium battery, electronics, or critical facility application.

Request Technical Consultation